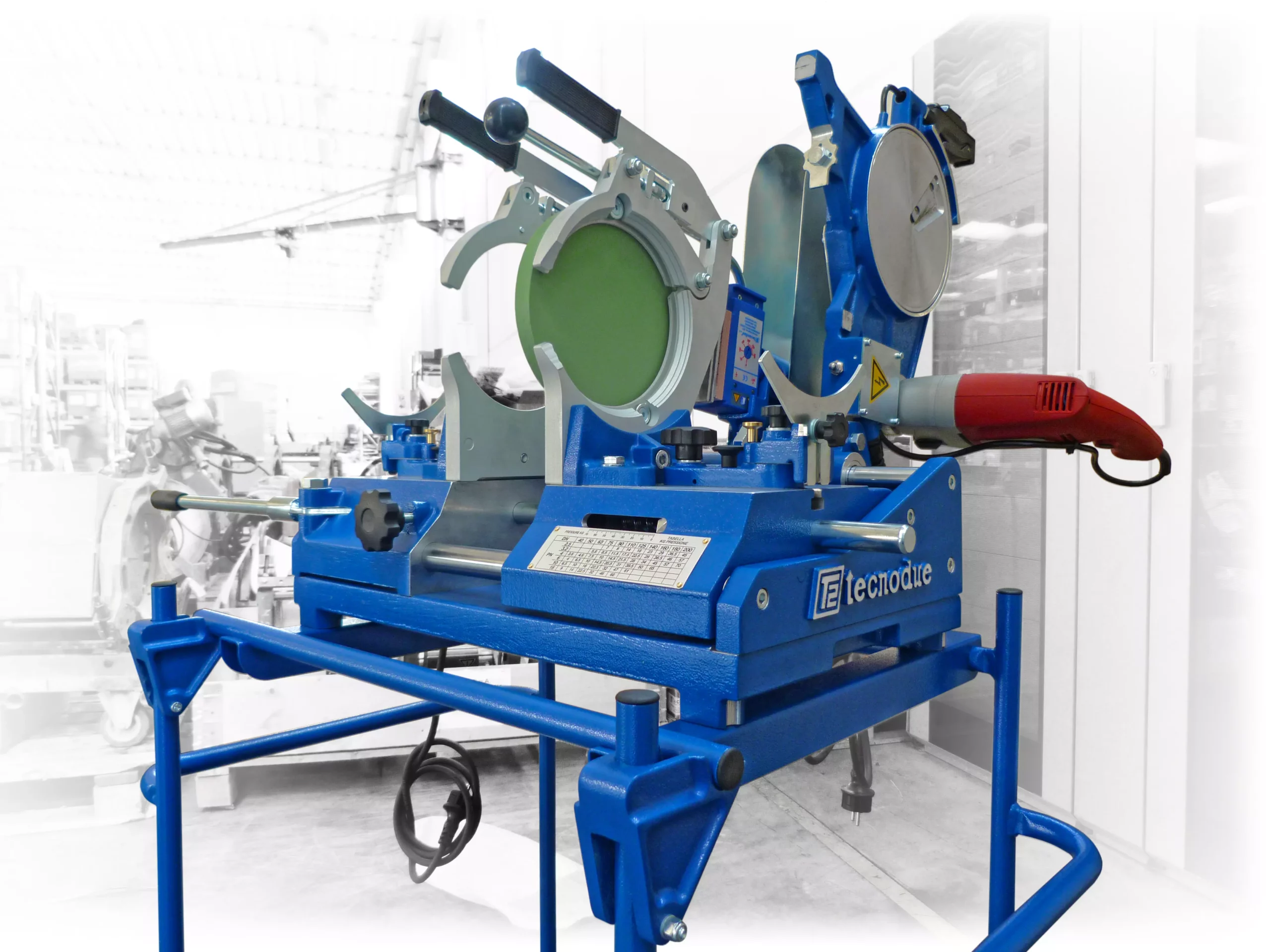

world 250 welding machine

Main features

Very solid and robust machine, suitable for workshop use, suitable for butt welding of small wall thickness pipes and fittings in polyethylene (PE) and polypropylene (PP) .

Clamps can both be rotated up to 7.5° for the construction of segmented bends (total angle: 15°).

Technical data

| Welding range | d. 40-250mm |

| Maximum Applicable Force | 140kg |

| Standard voltage | 230V - 50Hz |

| Power consumption | 3.1kW - 14A |

Machine composition

- Basic machine made up of two light alloy trolleys, one of which is mounted on axial bearings and runs on chrome plated rods d. 25mm. The translation lever, in addition to carrying out the movement, acts on an index which shows the welding values of the pipe to be welded on a graduated scale. The practical drawer contains all the reductions and accessories.

- Electric milling device with safety switch and activated by a button placed on the handle.

- Adjustable PTFE coated heating mirror that slides on rod d. 25 mm.

It is also easily removable for manual use. - Right and left clamps d. 250 mm pivoting up to 7.5°, therefore suitable for the construction of segmented bends (15° for each weld) and clamps reductions d. 180 - 200 - 225mm.

- Right and left clamps d. 160 mm equipped with a locking system that makes them suitable for welding short spigot fittings and can be rotated up to 7.5°.

- Clamps reductions d. 40 – 50 – 63 – 75 – 90 – 110 – 125 – 140 mm.

- Lateral supports and relative reductions for all diameters.