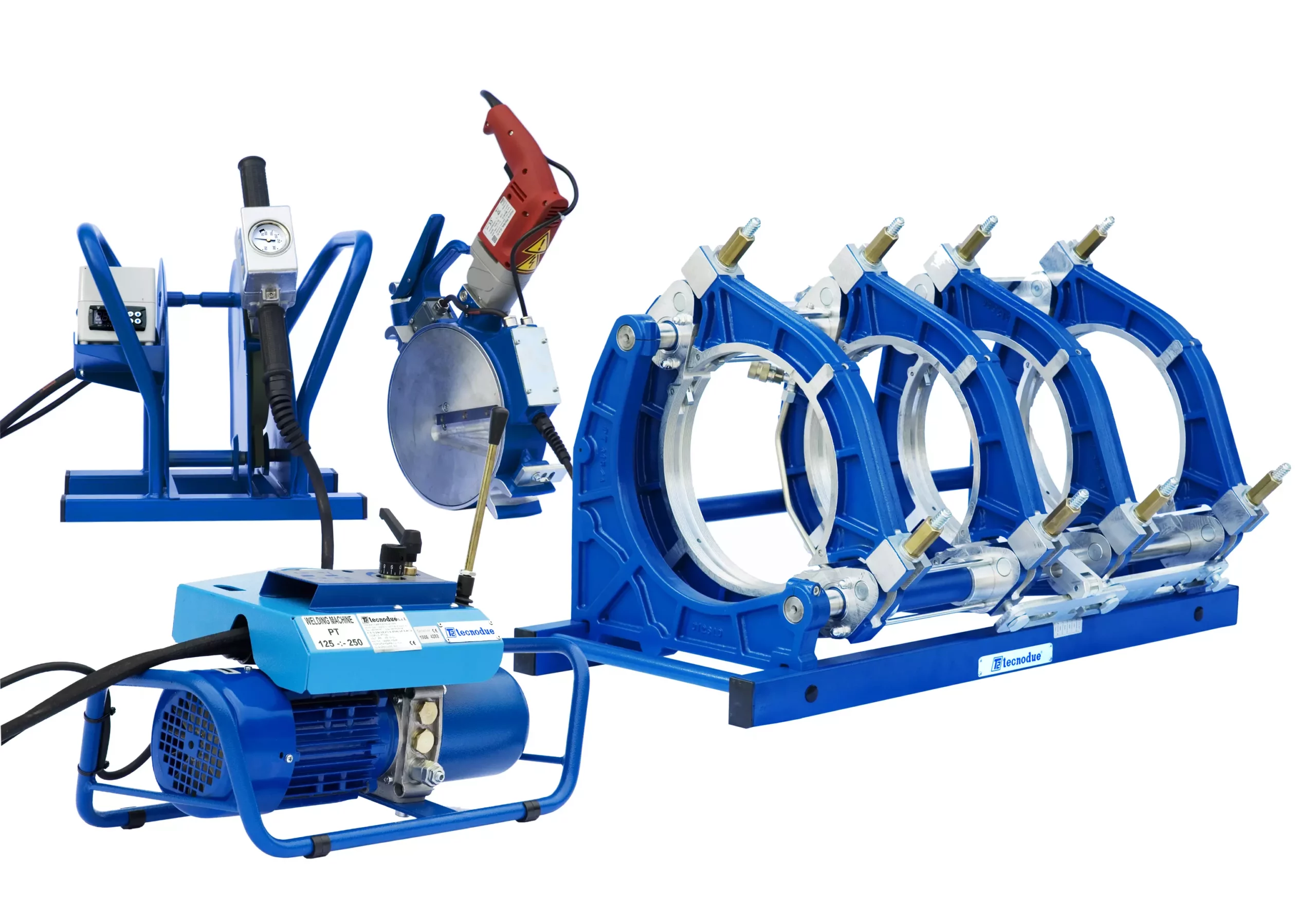

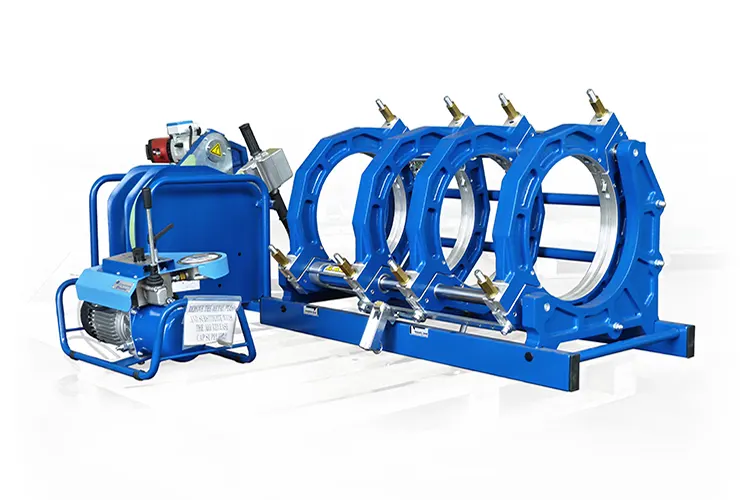

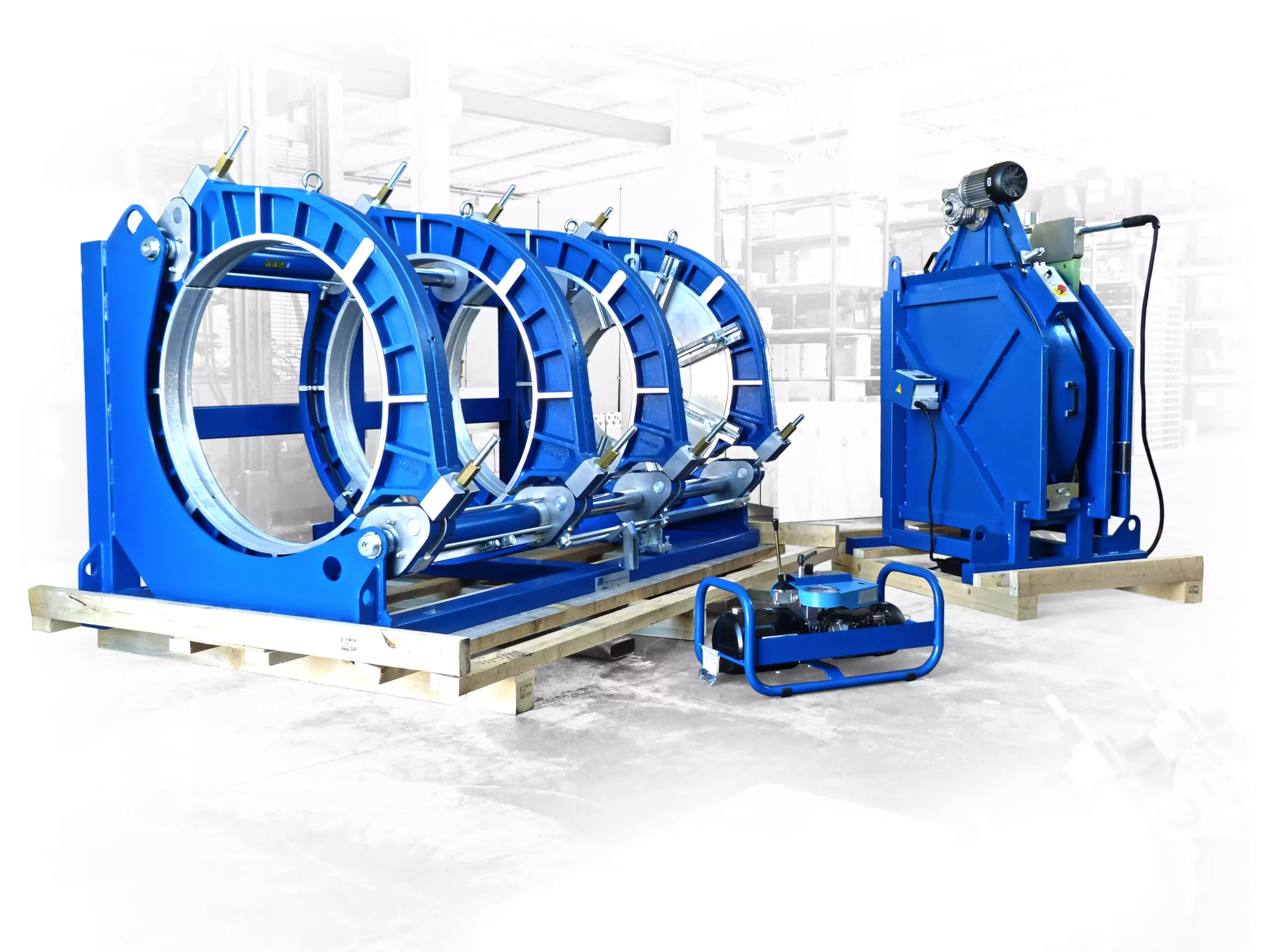

pt 1600 welding machine

Main features

Butt welder for pipes in polyethylene (PE), polypropylene (PP), PVDF and other thermoplastic materials for pressure pipelines (water, gas and other).

The self-aligning structure and inclined clamps allow you to operate in complete comfort.

The digital thermostat allows for quick setting of the temperature, which can also be viewed via the independent analogue thermometer and works even in the event of a power failure.

Electric milling device with safety microswitch, reversible blades and mill stop, which allows you to continue milling from one side only.

Hydraulic unit complete with accumulator, regulation valve and by-pass valve.

The aluminum reductions ensure maximum rigidity and are equipped with the Beep Beep screwless quick coupling and release system.

The welding machine is manufactured and tested in compliance with main regulations in force (UNI 10565 and CE safety regulations).

Technical data

| Welding range | d. 1000-1600mm |

| Operating pressure | 8-150 bars |

| Standard voltage | 400V 3ph. – 50Hz |

| Power consumption | 55kW - 85A |

| Total cylinder section | 69.08 sq.cm. |

Machine composition

- Basic machine d. 1600 mm with 2 cylinders, composed of four steel jaws and with automatic detachment device of the thermoplate.

- Removable electric cutter with stop and safety microswitch.

- Removable PTFE coated heating mirror with electronic temperature control and analog thermometer.

- Electro-hydraulic unit complete with pressure adjustment, by-pass valve and accumulator.

- Ground support for mirror and miller.

Common accessories

- Series of steel reductions for pipes and fittings available in diameters

1000 – 1200 – 1400mm. - Packing on pallets.