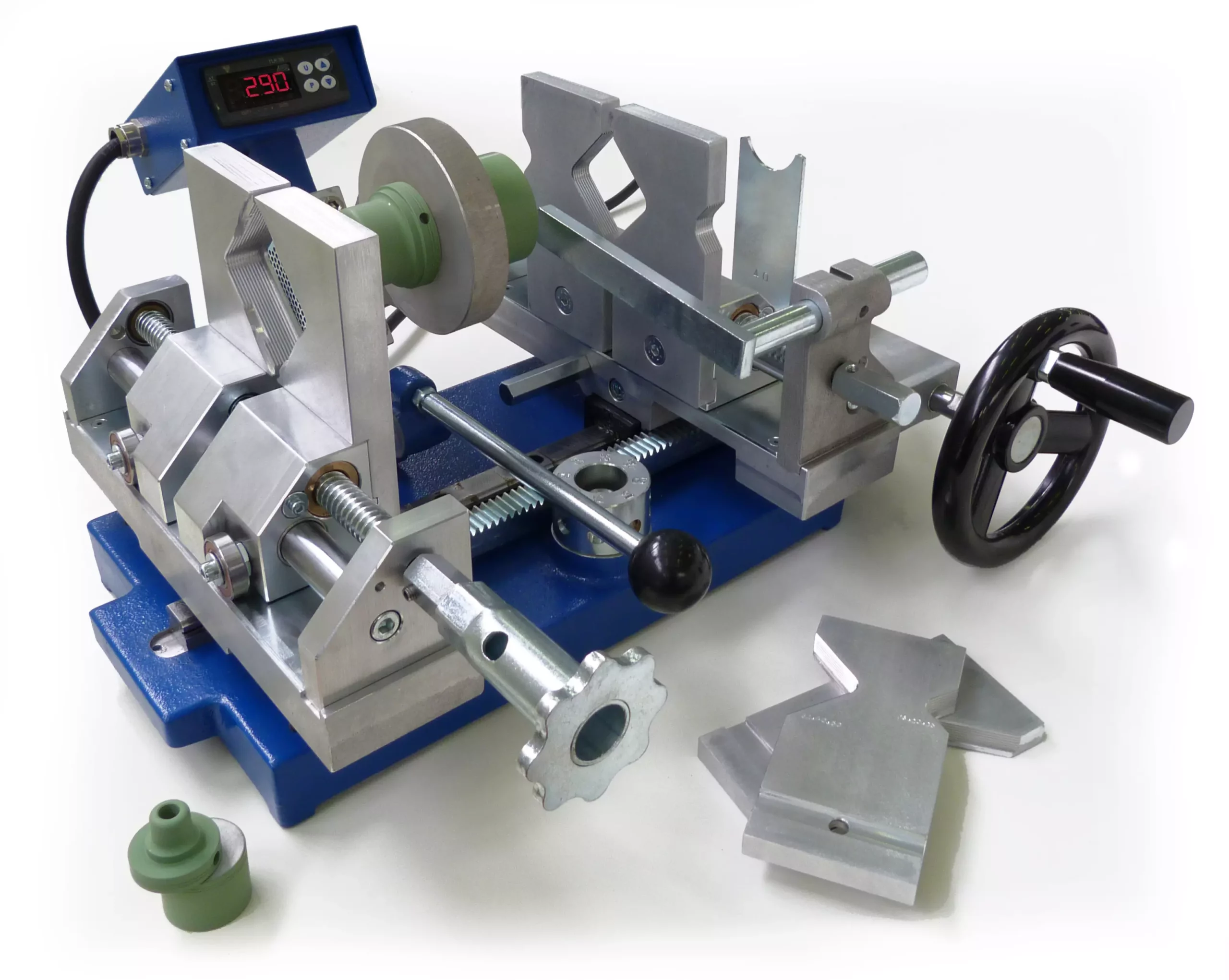

POLY 110 P welding machine

Main features

The machines of the POLY series are the ideal solution to the problems of polyfusion (socket) welding of pipes and fittings in PP, PE, and PVDF, both in thermo-sanitary and industrial applications.

They have a versatile and light structure and are equipped with a thermoplate with temperature regulation, which guarantees greater accuracy during the work phase.

The PTFE-coated bushes have the required shape in compliance with the strictest European standards including DVS 2208-1.

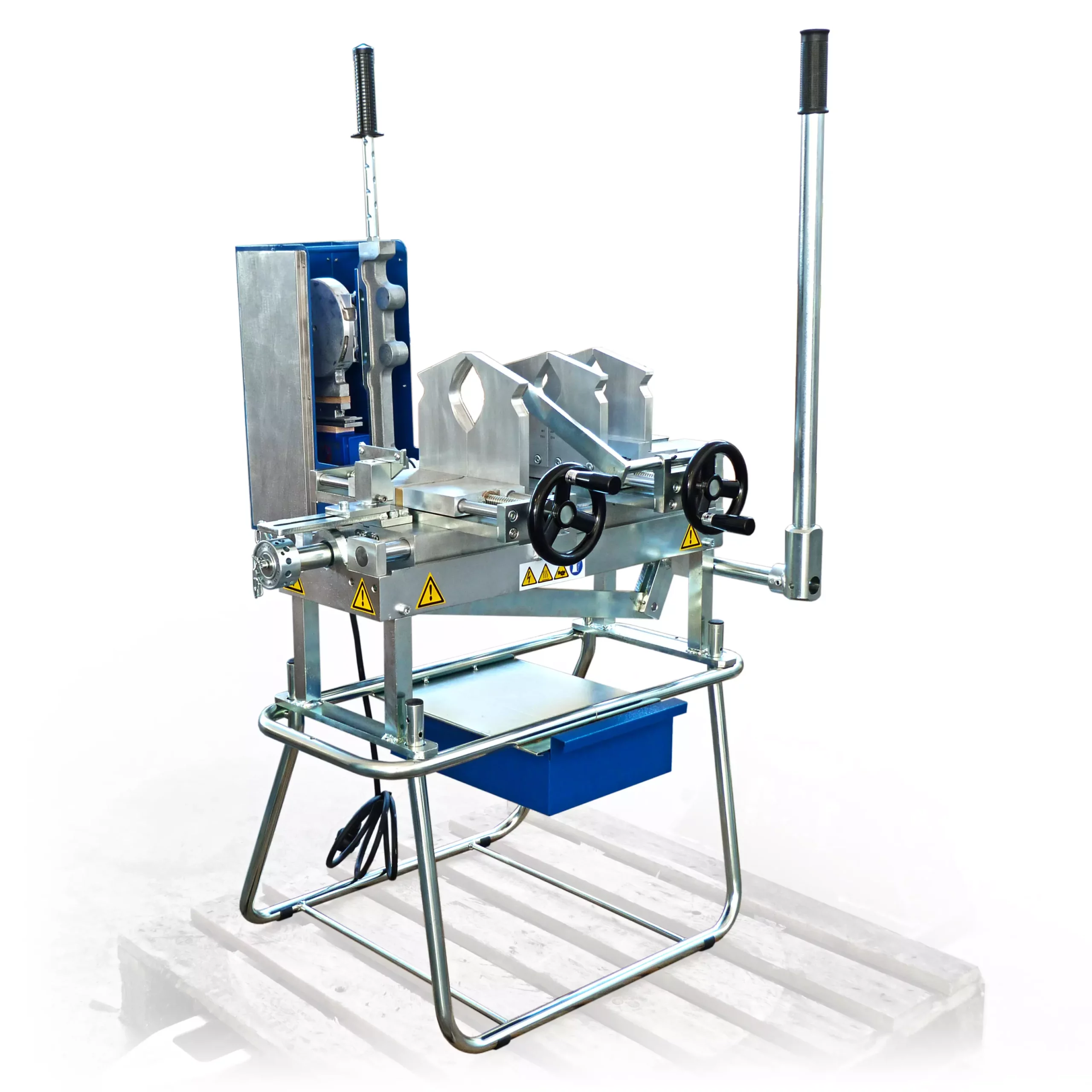

In the POLY 110P the movement of the machine is hydraulic and takes place via a control lever. It is equipped with a depth selector which automatically adjusts the depth according to the selected diameter, stops for positioning the pipe or fitting, prismatic clamps which allow the fixing of different types of pipes or fittings, adjustable mirror temperature .

Technical data

| Range | d. 16-110mm |

| Standard voltage | 230V - 50Hz |

| Power consumption | 2KW - 8.7A |

| Weight | 97kg |

Machine composition

- Machine for polyfusion (socket welding) of pipes and fittings in PP, PE and PVDF

both for thermo-sanitary and industrial applications. - It is also equipped with a side tube holder for all diameters.

- The Poly 110 is available in both a manually operated version (“Poly 110 M”) with a manual mechanical movement through a practical lever, and in the hydraulically operated version (“Poly 110 P”).

- Reference stops for positioning the pipe or fitting.

- Revolving heating mirror with mechanical temperature control.

- Pair of PTFE-coated bushes d. 16, 20, 25, 32, 40, 50, 63, 75, 90, 110mm.

- Wooden crate for transport (cm 90x72x108h)