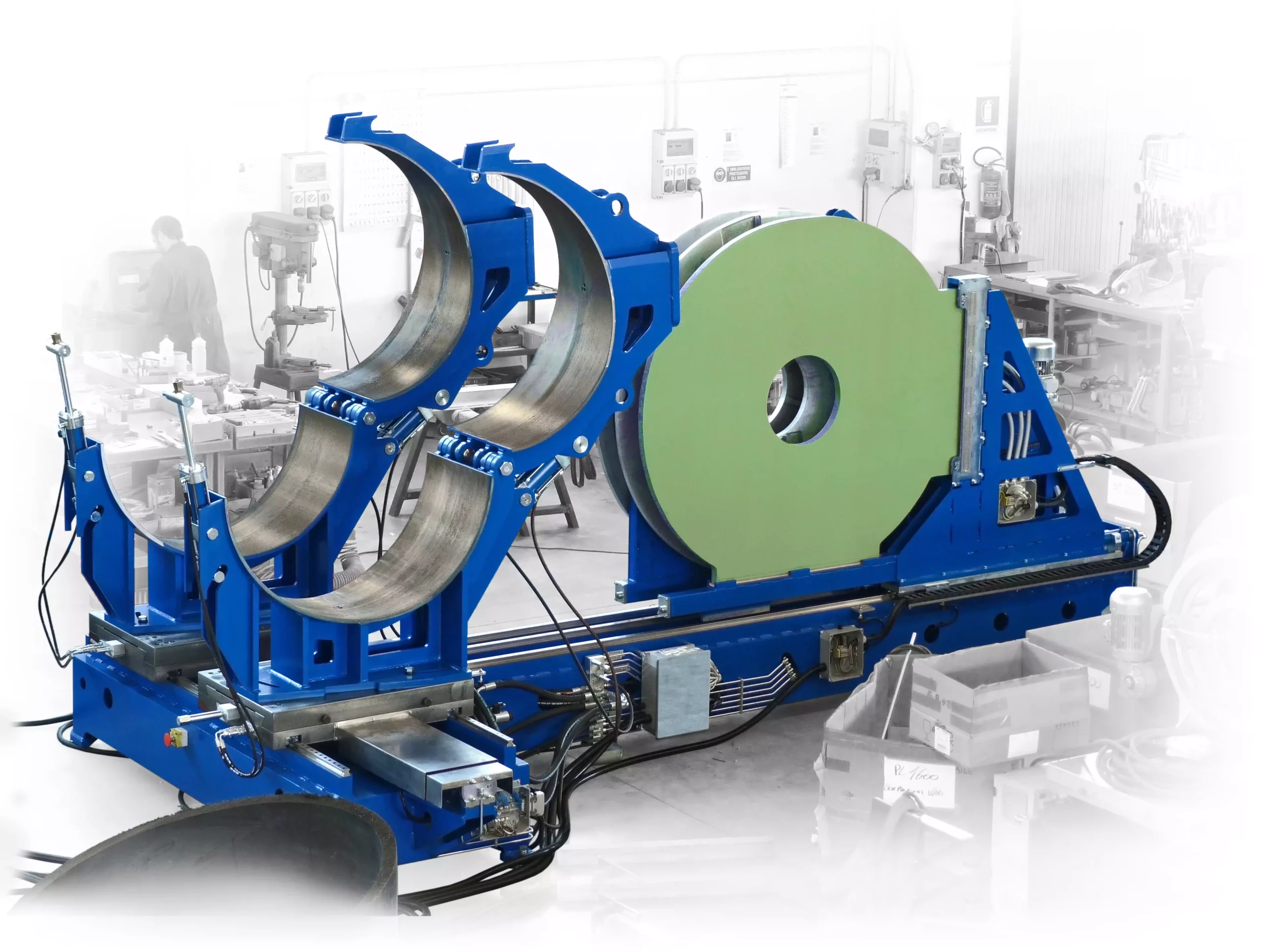

welding machine pl 160

Main features

Manually operated butt welding machine for pressure pipes (aqueducts, irrigation systems, ...) in PE (polyethylene) and PP (polypropylene).

The pivoting clamps allow the construction of segmented bends with different angles (max: 30°) in a wide range of diameters.

It stands out for its extreme practicality and manageability, thanks to its low weight (18 kg) and small size.

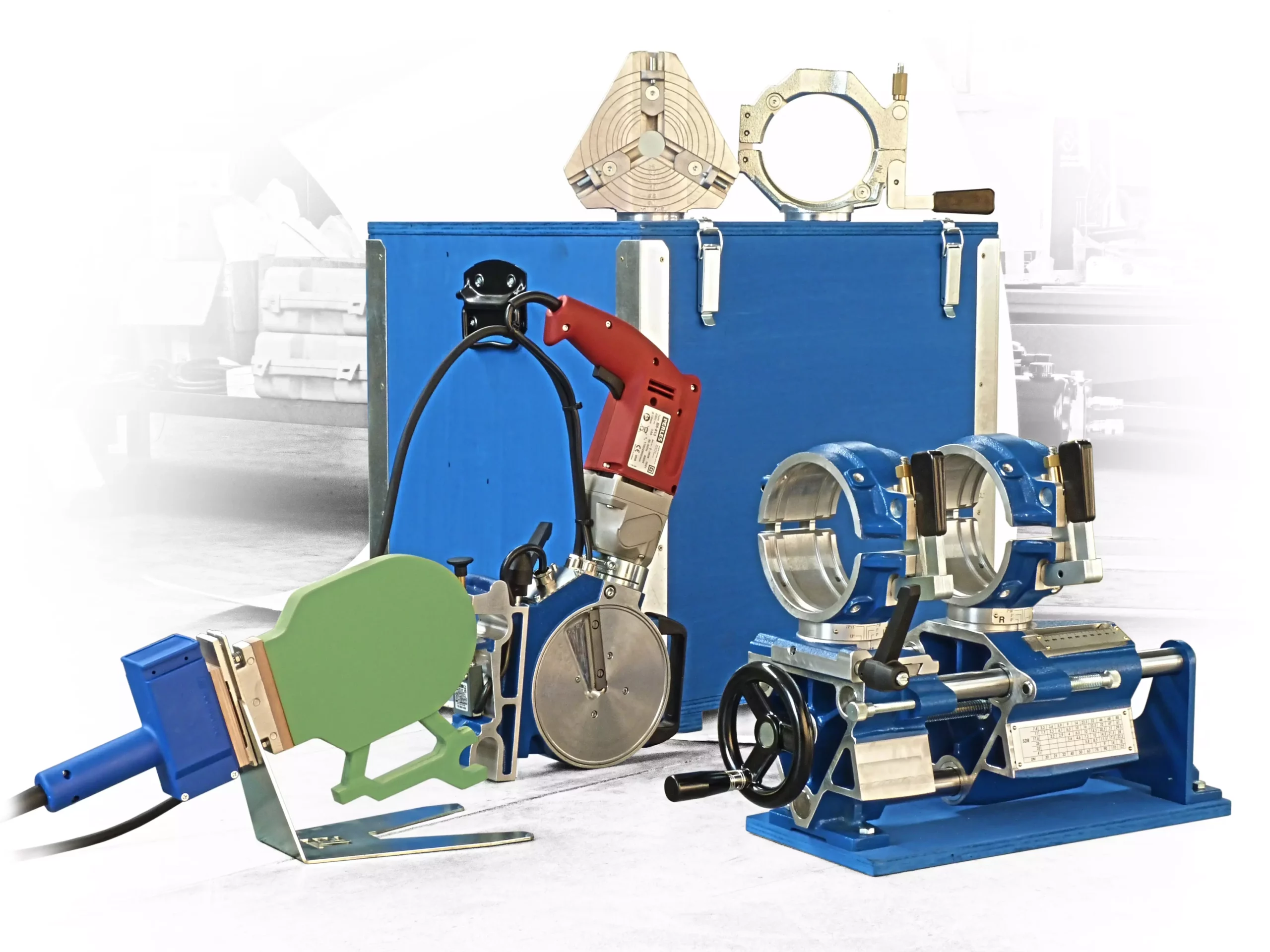

It is supplied in a sturdy wooden transport box, containing all the reductions and accessories, as well as the miller (electric) and the heating plate.

Technical data

| Welding range |

Straight welding, curves, fittings: 40 – 160 mm. Tee, Croci, Breeches: NO |

| Maximum Applicable Force | 140 Kg |

| Standard voltage | 230V - 50Hz |

| Power consumption | 2.1kW - 9.1A |

Machine composition

- Basic machine with manual movement.

- Two rotatable jaws d. 160 mm suitable for butt welding and the manufacture of sector bends with different radii of curvature.

- Reductions for rolling jaws d. 40 – 50 – 63 – 75 – 90 – 110 – 125 – 140 mm.

- Removable electric mill with reversible blades and safety micro-switch.

- Removable PTFE coated heating mirror with adjustable temperature.

- Wooden crate for transport.

Accessories on request

- Right/Left Fittings clamp d. 160 mm for fittigins and relative reducitons 40-140 mm.

- + Stub end device d. 40-160mm.

Models Series

PL series

PL 125

Welding machine PL 125 Features: Manually operated butt welding machine for pipelines (aqueducts, irrigation …

PL series

PL 160

welding machine pl 160 Features Manual butt welding machine for pressure pipelines (aqueducts, systems …

PL series

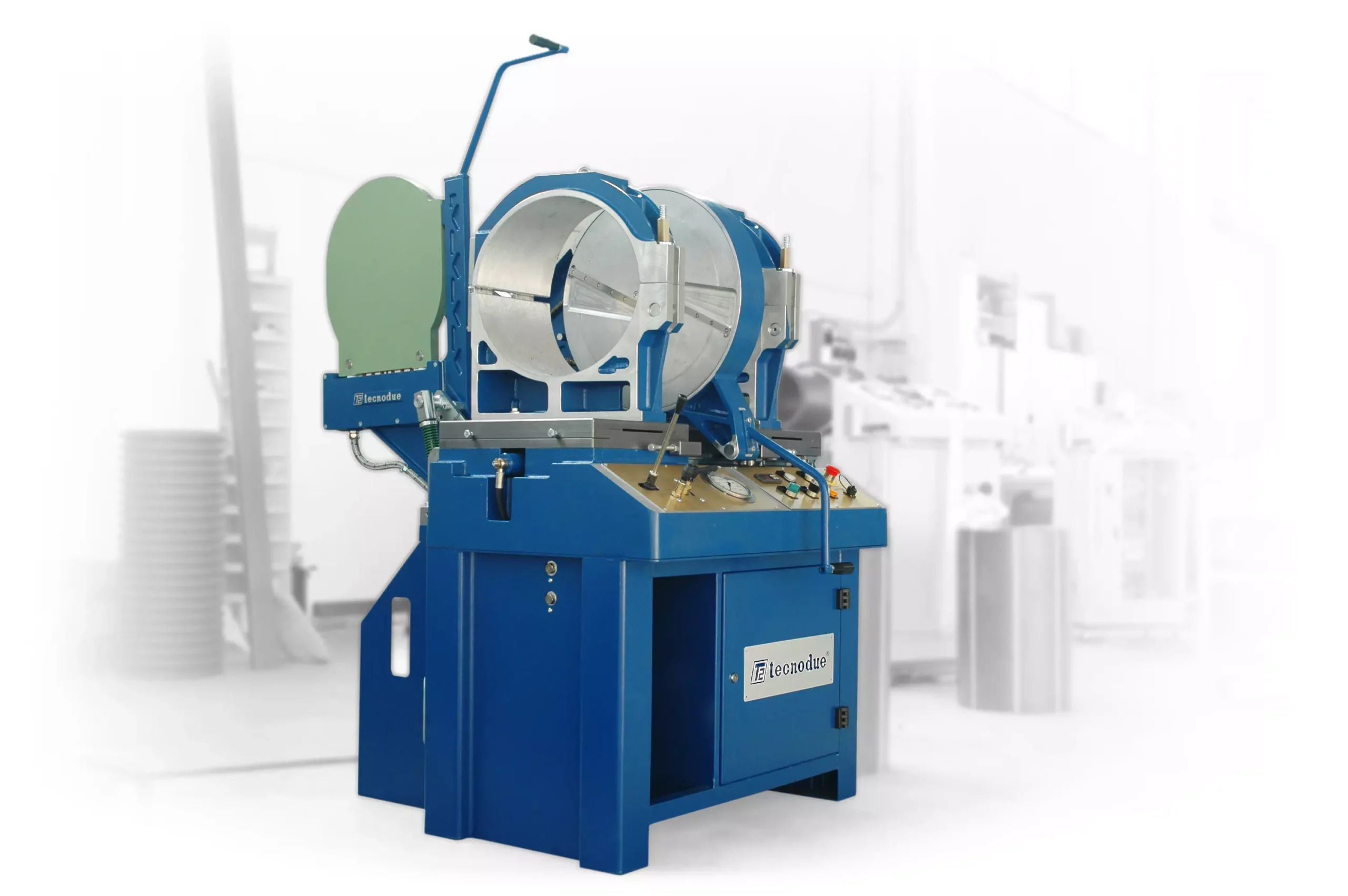

PL 315 C

Welding machine PL 315 C Features: Workshop butt welding machine for the construction of …

PL series

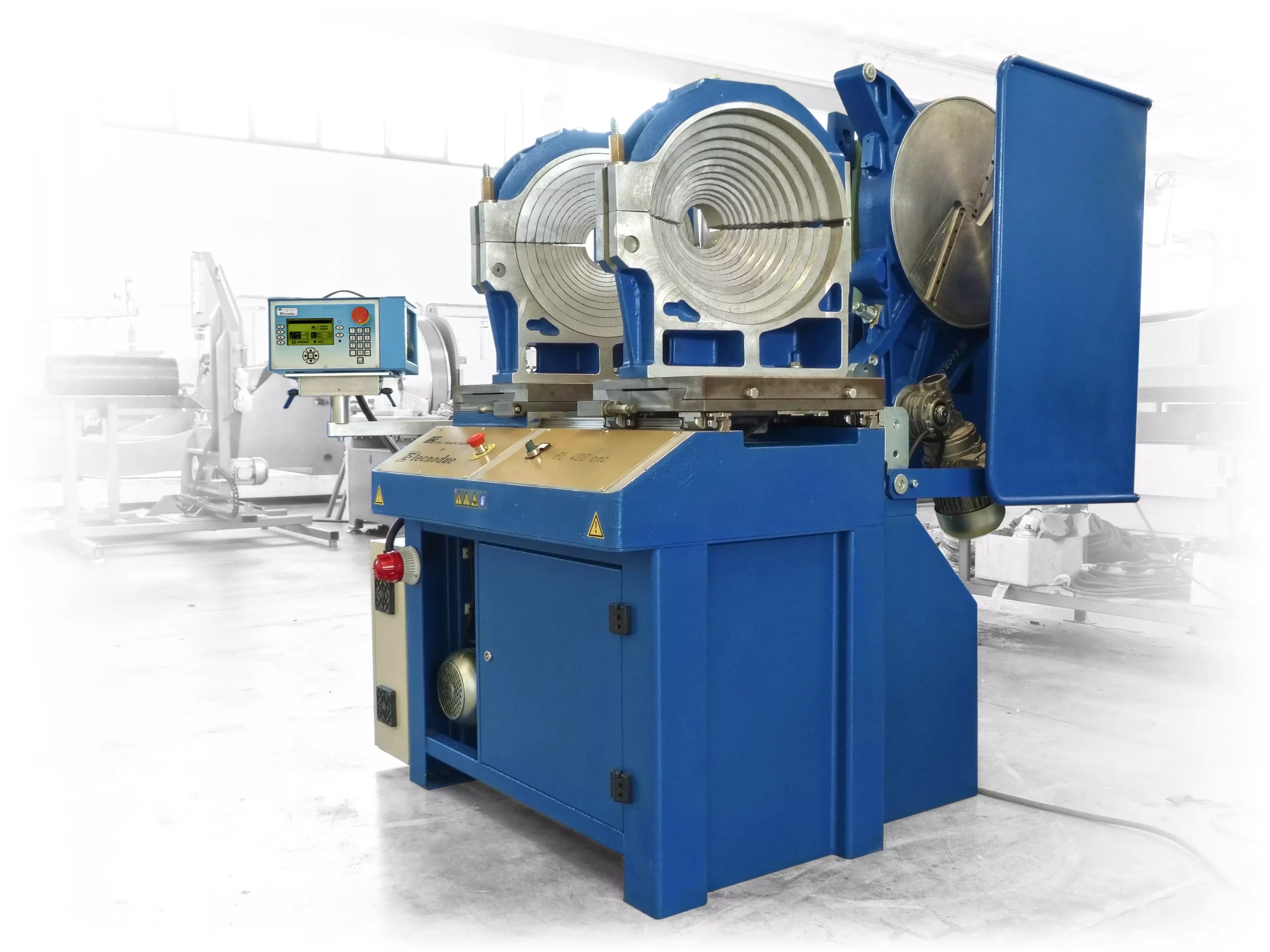

PL 315 CNC

welding machine pl 315 cnc Features Laboratory butt welding machine for the construction of …

PL series

PL 400 C

welding machine pl 400 c Features Laboratory butt welding machine for the construction of …

PL series

PL 400 cnc

welding machine pl 400 cnc Features Laboratory butt welding machine for the construction of …

PL series

PL 500 cnc

welding machine pl 500 cnc Features Laboratory butt welding machine for the construction of …

PL series

PL 630 cnc

Welding machine PL 630 CNC Features: Workshop butt welding machine for the construction of ...

PL series

PL 800 cnc

Welding machine PL 800 CNC Features: Workshop butt welding machine for the construction of …

PL series

PL 1000 cnc

Welding machine PL 1000 CNC Features: Workshop butt welding machine for the construction of …

PL series

PL 1201 cnc

welding machine pl 1201 cnc Features Laboratory butt welding machine for the construction of …

PL series

PL 1600 cnc

Welding machine PL 1600 CNC Features: Workshop butt welding machine for the construction of …

PL series

PL 2000 CNC

SPECIALE pl 2000cnc welding machine Features CNC automatic laboratory welding machine for PE, PP, …